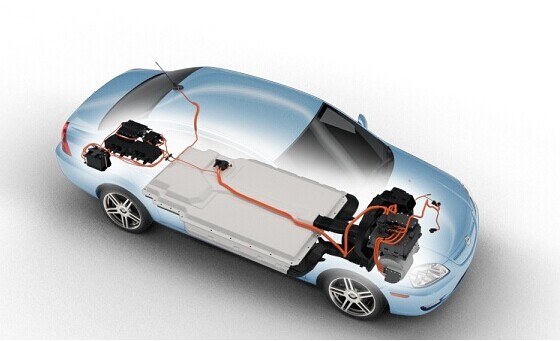

In the pre-architecture development of pure electric vehicle projects, reasonably arranging the integrated power lithium-ion battery pack is crucial, specific working elements, importantly involving ground clearance, passability, crash safety and power requirements, etc., which will be introduced separately below.

1. Ground clearance requirements of the battery

In the case of a structural member protecting the lower surface of the battery, the following conditions must also be met:

Under the state of maximum up-jump, the battery must be guaranteed a certain clearance from the ground.

Competitive ground clearance is guaranteed under full load.

The battery RESS must be protected in the positive direction.

The battery RESS arrangement must not be lower than the lowest surface of the surrounding body structure.

2. Restrictions on the Z-directional size of the battery by the occupant compartment man-machine arrangement

The man-machine arrangement of an electric vehicle project can be seen to have a total of nine engineering indicators to be considered in the Z-directional latitude, specifically the distance from the occupant's H-point to the ground H5, the occupant's sitting height H30, the headspace H61, the distance from the heel point to the ground H8, the battery pack Z-directional thickness, the battery pack ground clearance, the vehicle height H100, the distance from the upper surface of the lithium-ion battery pack to the upper surface of the floor, and the carpet and acoustic foam thickness. The body's height is thus defined according to the styling requirements, and the Z-directional dimensional limiting surface of the battery pack can be introduced according to the man-machine arrangement requirements.

3. Restriction of the Y-directional size of the battery by the collapsed space

Is the working voltage of the battery generally higher than 300? V, coupled with the high corrosiveness of the electrolyte in the battery cell, the lithium-ion battery pack should be set up with a reasonable safety collapse gap when the whole vehicle is arranged, with the lateral collision conditions being particularly demanding. Specific models should be analyzed by CAE iterative means to arrive at a good design of the lateral collapse distance from the battery to the door sill plate.

4. Limitations of the whole vehicle load transfer path on the battery pack design

The whole vehicle load transfer path can be roughly broken down into front compartment load paths, front mid-floor load transfers, and rear floor load paths. As the future lithium-ion battery pack arrangement method is laid flat under the floor, the front mid-floor load transfer path design is closely related to the battery pack structure method.

After topology optimization, regarding the load transfer under the floor, it is important that the load transfer is done by arranging the longitudinal beam extension beams on the side of the battery and the 1.5 beams in front of the storm, as shown in Figure 8, in which the purple longitudinal shaft is connected to the front cabin longitudinal beam through the triangular structure and the 1.5 beams for frontal impact load transfer; at the same time the battery frame should also be used as a load transfer path together with the body load-path; the battery pack The internal beam structure should be aligned with the position of body beams 2/3/4 and the central access beam.

5. Range regarding power requirements

For the same battery cell module, the range is related to the energy density and capacity of the battery, which in turn is determined by the number and manner of series and parallel connections of its internal cells, ultimately leading to changes in the overall shape and size of the powerful lithium-ion battery pack. Table 2 details the power and pack size variation due to the different energy densities and series-parallel connection methods of the cells and modules of other suppliers' packs under the same range of target requirements.

6. Battery pack installation interface requirements

The installation of the powerful lithium-ion battery pack on the vehicle directly affects its modalities and strength. Generally, a mounting point should be arranged at intervals around the box. If the overall pack length is greater than 2mm, it is recommended that a new hanging point be added in the middle to improve the modalities.

The powerful lithium-ion battery pack is the core energy source of the new energy vehicle, supplying the car with driving electricity. It is mainly made up of the main body of the battery pack through the metal shell envelope.

Next:What is the correct way to use a lithium battery electric car?

Previous:What are the charging misconceptions about lithium batteries?

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |