On September 4, local time, the globally influential 2023 Munich Auto Show in Germany (IAA Mobility 2023) opened. CALB participated in the exhibition with a series of core products and solutions in the field of power batteries, focusing on the world's original OS batteries, "top-class" cylindrical batteries, as well as full-tab laminated batteries, 4C fast-charging batteries, PHEV-specific batteries & systems and solid-state, Lithium-sulfur battery products and VDA standard modules have received widespread attention and consultation from visitors. Among them, the most cost-effective OS batteries and the "top-flow" cylindrical batteries with leading performance that have achieved mass production have attracted much attention.

On September 6th of the same period, WNEVC2023 (IAA Mobility Special) with the theme of "Low Carbon Travel, Win-win Cooperation" opened wonderfully. CALB Chairman Liu Jingyu was invited to give a keynote speech at the conference, focusing on the company's power battery technology and products The innovative situation has helped the electrification process in Europe and the world enter a new stage. The following are excerpts from the speech:

Under the global trend of "emission reduction and carbon reduction", the electrification transformation of the automobile industry can contribute low-carbon power to green and sustainable development. As an important influencer of power battery technology, CALB has been thinking about how to make due contributions to this industry. We have a dream - "Beyond business and benefit mankind", and we have an ideal - "Create win-win results and achieve greatness". We believe that technological innovation in the field of power batteries will play a positive role in accelerating the electrification of vehicles.

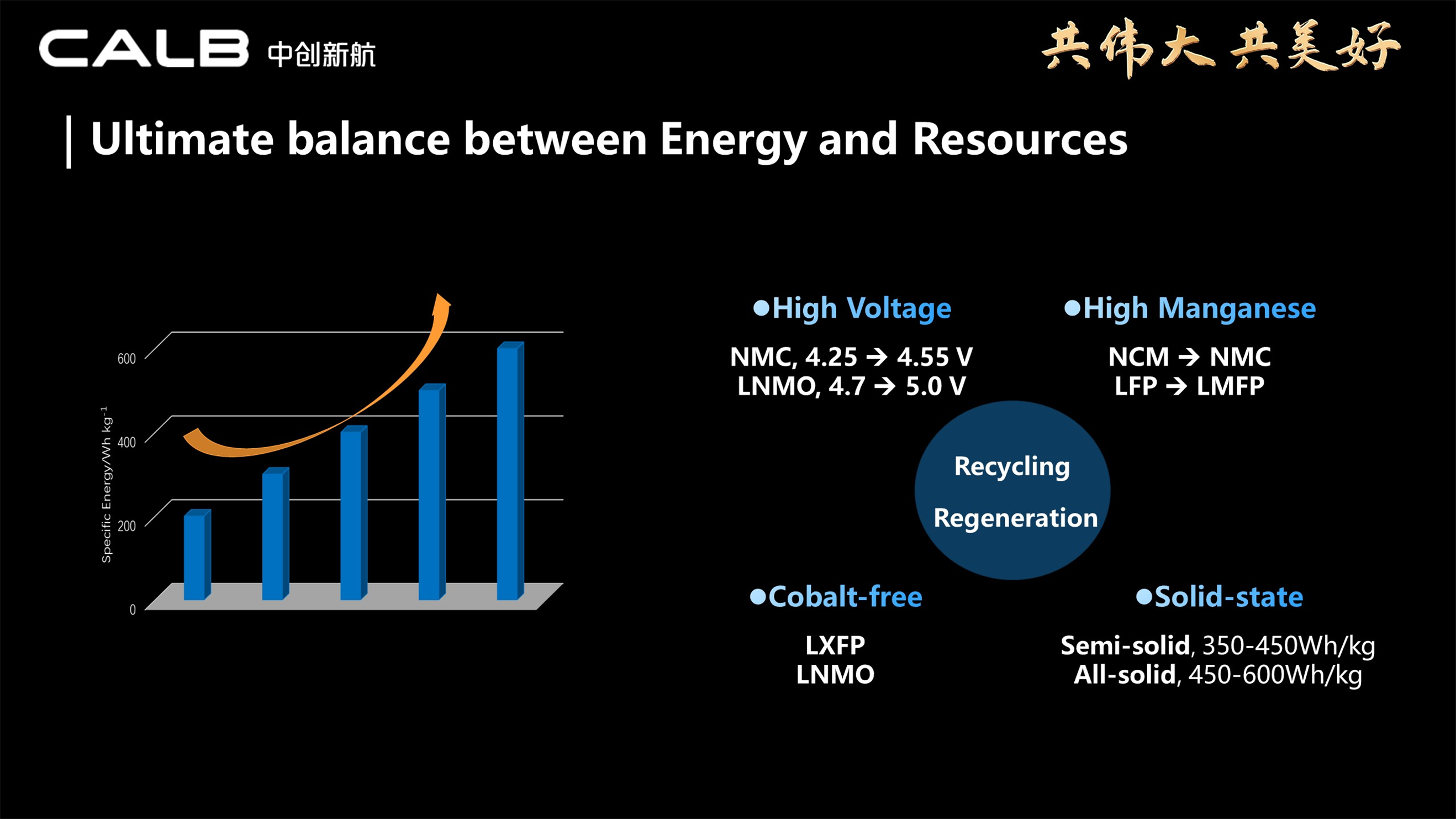

The ultimate balance of energy and resources - the road to sustainable development of power batteries

With the rapid increase of new energy vehicles, how to make the ultimate use of resources and achieve the ultimate balance between energy and resources is a question we have been thinking about, and it is also an important driver of our technological innovation.

CALB insists on taking the needs of end users and customers and sustainable social development as the fundamental pursuit of technological development. In the process of material innovation, structure and manufacturing technology innovation, it always pays close attention to product safety, power performance experience, resource utilization efficiency, Product life cycle cost. Based on these thoughts, our research on materials and chemical systems is mainly reflected in four aspects: high pressure, high manganese, cobalt-free and solid state:

High-voltage ternary lithium battery technology was launched under the concept of the ultimate balance of high energy and resources, as well as the ultimate balance of high energy and safety. This innovation has made a substantial contribution to the industry. We are the first company to increase the energy density of medium-nickel 5-series products to a level comparable to high-nickel 8-series products, and the first company to adopt high-voltage 5-series products to achieve a 600km range. After continuous iterative upgrades, the 6-series high-voltage products we launched can reach the level of 300Wh/kg and support a battery life of more than 1,000km. With the continuous advancement of technology, China Nickel's high-voltage products can meet the long-range and high-performance requirements of most car models.

High voltage technology has effectively improved the energy efficiency of lithium, nickel and other resources, thereby significantly reducing costs. With the advancement of high-pressure technology, lower-cost, environmentally friendly manganese will play an increasingly important role. The chemical system of medium-nickel and low-cobalt layered ternary materials with a manganese content of more than 30% and phosphate materials (LMFP) and spinel materials (LNMO) with a manganese content of more than 70% will become high-specific energy, high safety, A mainstream solution with efficient resource utilization and low cost.

Facing the demand for higher energy density, it has become inevitable to match 9-series high-nickel with silicon-carbon negative electrodes, or even use lithium metal. The development of battery intrinsic safety technology will be decisive at this stage. Currently, the battery we have developed using lean liquefaction technology and having an energy density of 350Wh/kg does not catch fire when pierced by the acupuncture test. The thermal safety performance of the battery reaches a level equivalent to that of medium-nickel ternary; batteries using semi-solid technology have an energy density of 350Wh/kg. The density can reach 450Wh/kg, which is expected to achieve better thermal safety performance; using all-solid-state battery technology using composite metal anodes, the energy density can reach 600Wh/kg, showing higher safety performance and greatly improving cycle life.

The above shared how to obtain higher energy with fewer resources, especially scarce resources. In fact, in the development process of materials and chemical systems, we also take the high degree of standardization and recyclability of the material chemical system as important considerations. With the advent of the TWh era, the recycling of resources is receiving more and more attention. The efficient recycling of battery materials is an important support for the sustainable development of future power batteries.

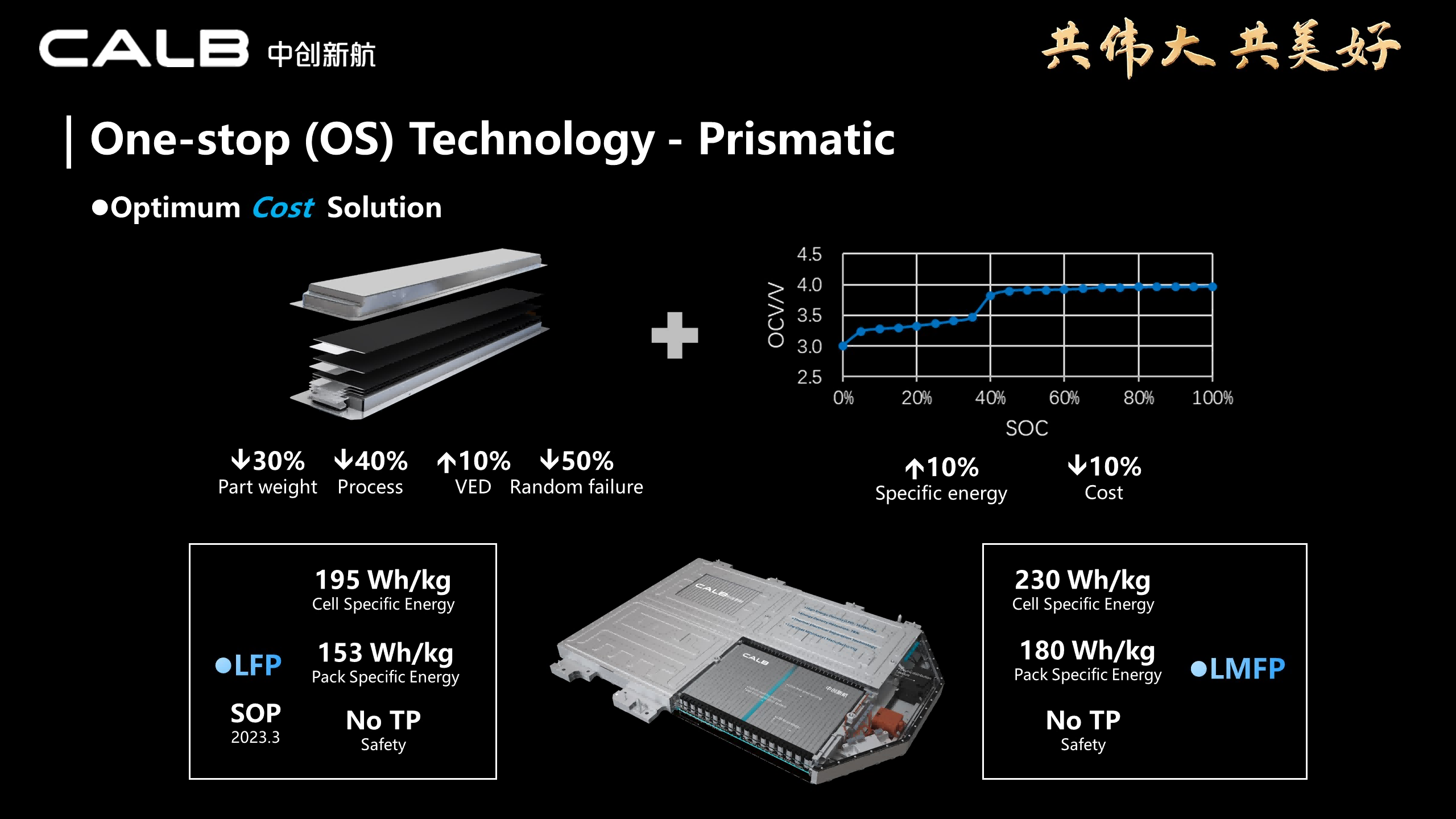

OS products - minimalist design & extreme manufacturing to create the optimal cost solution

What was shared earlier is innovation in materials and chemical systems. Innovation at the structural and manufacturing levels are also important aspects of CALB's innovative development concept. less is more! In the process of exploring the ultimate cost solution, we focus on the high integration of design and manufacturing. Starting from the underlying functions of the product and basic technical principles, we reconstruct the product design and manufacturing process, and propose the One-stop design concept, that is: function The high degree of integration simplifies product design, manufacturing process, and production equipment, reduces the complexity of products and processes and the intensity of unit fixed asset investment, and achieves high stability, high reliability and low cost of large-scale production. And developed a series of key technologies covering new structures, new equipment, and new processes. Our current mass-produced first-generation OS batteries have simplified the number of parts by 25%, the number of processes by 40%, and the corresponding manufacturing costs have been reduced by more than 10%. OS batteries perfectly take into account the special requirements of modular system integration. The modular-less CIR battery system we have mass-produced has reduced the number of parts by more than 10% and simplified the manufacturing process by 25%. We are the first to integrate LFP battery systems The energy density is increased to 153Wh/kg.

Currently, Lifepo4 battery has become the mainstream in the battery life range within 700km. With the development of high-manganese iron lithium technology, the energy density of OS cells will reach 230Wh/kg, and the energy density of high-manganese iron lithium-CIR battery systems will exceed 180Wh/kg. At the same time, the cost will be further reduced by more than 10% compared with the current LFP. We believe that high manganese iron lithium-CIR technology provides the best systematic solution for low-cost applications and will become the mainstream in the range of 800km.

"Top-class" R46 large cylindrical battery - the best solution for high-performance application scenarios

In addition to being extremely cost-oriented and facing the high-end demand for high performance, we have proposed the industry's first "top flow" structure and 46 series large cylinder technology. The integrated assembly and linkage welding technology of the pole lug-collecting plate-cover plate is used to achieve functional integration to the greatest extent. Through minimalist manufacturing, manufacturing efficiency is increased by 50%. Compared with the "poleless ear" structure, the current flow path of the "top flow" structure is shortened by 70%, and the internal resistance of the structure is reduced by 50%, which greatly reduces the heat generation of high-power charging and discharging; the "Z" utilization rate is as high as 87.5%, and the power The core energy is significantly improved; the "top flow" design prevents the casing from acting as a flow guide component and uses stainless steel as the casing material to achieve "zero" corrosion and high reliability; the fast charging capacity exceeds 6C, which greatly alleviates users' energy replenishment anxiety. A truly worry-free journey.

"Top-flow" large cylinders bring the best solution to high-performance application scenarios, capable of achieving high specific energy of more than 300Wh/kg, safety performance without heat spread, 6C fast charging experience, higher manufacturing efficiency and height Standardized structural dimensions.

In addition to the above thoughts and practices in technological innovation and product innovation, we are also well prepared to provide supporting services in Europe. CALB's first overseas production base has been promoted as planned in Portugal, with the first phase of construction of 15GWh production capacity. Subsequent expansion will be based on market size and customer demand.

Green and sustainable development is the company’s development philosophy. We have carried out a lot of work in reducing emissions and reducing carbon emissions. We have also paid attention to the requirements of relevant European laws and regulations. In terms of carbon footprint, battery passport, battery recycling, material recycling and reuse, responsible supply chain, etc., a large number of specific technical and management arrangements have been implemented and obtained. highly praised by industry organizations.

We always adhere to the concepts of green, low-carbon and sustainable development, insist on technological innovation, and look forward to continuing to contribute CALB to the healthy development of the industry.

Next:LFP battery overseas market penetration accelerates

Previous:Waterproof 150W Wireless Charger for Smart Farm Robots in Korea

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |