CATL's Kirin battery, a cutting-edge technology, has achieved mass production.

On January 11th this year, CATL revealed on its interactive platform that the Kirin battery was expected to begin mass production in the first quarter of 2023. Now, it seems that the mass production plan for the Kirin battery is proceeding as scheduled.

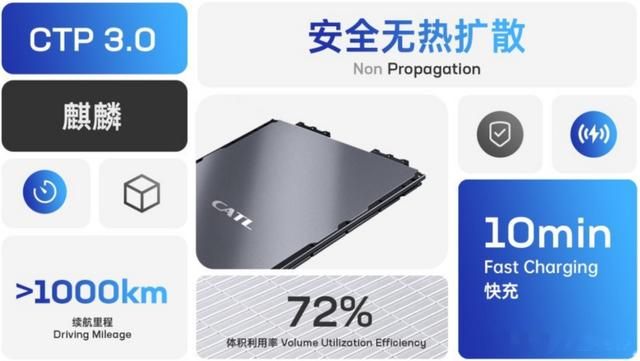

The Kirin battery is CATL's CTP3.0 version of its non-module battery pack, which was released on June 23rd last year and has caused a lot of discussion in the market since its release. CTP stands for "Cell to Pack", which is a non-module power battery pack. Compared to the traditional "cell-module-battery pack" three-level structure, CTP technology eliminates or reduces the module assembly process, directly integrating the cells into the battery pack, making it suitable for both lithium iron phosphate batteries and ternary batteries.

By eliminating the module shell wrapped around the cell, the battery pack has more space to arrange the cells, increasing the overall energy density and improving the driving range. At the same time, the number of parts in the battery pack has been greatly reduced, reducing manufacturing costs and weight.

Compared to the first two generations of CTP technology, the Kirin battery completely eliminates the module design and further improves safety, battery life, fast charging performance, and specific energy density through cooling structure optimization.

According to reports, the volume utilization rate of the Kirin battery has exceeded 72%, and the energy density of ternary cells can reach 255Wh/kg, while that of lifepo4 battery systems can reach 160Wh/kg. By comparison, the NIO ET5 100kWh version equipped with CATL's ternary lithium battery has an energy density of 185Wh/kg, while BYD's Han, equipped with a lithium iron phosphate blade battery, has an energy density of 150Wh/kg.

The goal of the Kirin battery is to fit more square cells into a limited volume, achieving a higher battery count. It is reported that the battery pack integration of the Kirin battery is currently the highest in the world, with a volume utilization rate exceeding 72%. It can increase the energy density of lifepo4 battery systems to 160Wh/kg and that of ternary battery systems to 255Wh/kg, achieving a range of 1,000 kilometers for the whole vehicle. Under the same chemical system and equivalent battery pack size, the Kirin battery's capacity will increase by 13% compared to the 4680 battery system.

In addition, the Kirin battery adopts the world's first large-area cell cooling technology, which can support 5-minute rapid heating and 10-minute fast charging.

Non-module and integration will become the trend of battery structure innovation.

From CATL's CTP1.0 in 2019 to CTP3.0 in 2022, Tesla's CTC plan in 2020, and BYD's CTB plan in 2022, the technology roadmap of major players in the new energy industry has become more diverse, indicating that the innovation of battery system structure has become more diversified. On the other hand, the overall direction of innovation is characterized by non-module and integration.

According to the analysis of the research department of Zhongjin Securities, in the previous battery technology cycle, material innovation led by high-nickel ternary was the main driver, while at the current point, material-level innovation iteration has slowed down, and structural innovation has accelerated. From the cell level, new structures such as 4680 and blades to the system level, CTP and CTC technologies will become the main line of this round of battery technology cycle.

From the current perspective, there are four types of innovative battery system structures, including CTP, CTC, CTB, and MTC.

CTP (Cell to Pack): Typical representatives are Contemporary Amperex Technology's (CATL) Blade Battery used by SAIC Motor and BYD, which eliminates the module assembly process and directly integrates the battery cells onto the pack while keeping the battery tray and top cover design.

CTC (Cell to Chassis): Tesla launched the CTC scheme based on the 4680 cylindrical battery in 2020, which directly arranges the cylindrical battery cells on the vehicle body to form a battery compartment, with large castings connected to the front and rear of the vehicle body, and the battery cover replaces the vehicle floor, reducing weight by 10%, increasing range by 14%, and reducing cost by 7%.

CTB (Cell to Body): BYD launched the CTB scheme in May 2022, which is first used on the Dolphin model. This scheme integrates the Blade Battery's top cover and the car body bottom plate into one, eliminating the separate top cover design while retaining the battery tray. The CTB scheme further improves the battery pack's space utilization rate to 66% and increases energy density by 10%.

MTC (Module to Chassis): Leading Chinese EV maker, Leapmotor, launched the MTC scheme in April 2022, which retains the module and battery tray design, uses the car body chassis as the battery pack's outer shell, and eliminates the separate outer shell, reducing the number of components by 20% and increasing the battery layout space by 14.5%.

According to the research department of China International Capital Corporation, compared with various CTP and CTC schemes, the cooling effect, heat dissipation performance, and battery life of CATL's Blade Battery and Tesla's 4680 CTC are superior. However, the Tesla 4680 CTC scheme has a slightly lower system energy density than the Blade Battery because of the naturally occurring gaps in the cylindrical arrangement, and lower grouping efficiency compared to a square cell design.

CATL has reached cooperation agreements with multiple brands, with the global mass production of Leapmotor's JiKe 009 MPV being the first to use the Blade Battery. The first mass-produced vehicle equipped with the Blade Battery is expected to be delivered in the second quarter of this year, about one to two months later than the original schedule.

In addition, the 2023 Leapmotor JiKe 001 WE version 100 kWh model can be equipped with a 140 kWh CATL Blade Battery, with a limited availability of 1000 sets of 1000 km range packages. After selecting the Blade Battery, the vehicle's comprehensive working condition range can reach 1032 km.

Moreover, CATL will also provide batteries for the AITO Wenjie series of new car models by Seres Group, and the two companies have signed a five-year long-term strategic cooperation agreement.

On the day of CATL's Blade Battery launch, Ideal Auto and NIO frequently interacted with CATL's official Weibo account and even used slogans such as "CATL has ideals" and "CATL goes to the mountains and the sea together." It is expected that more information about the models and timing will be disclosed in the future.

Next:Winston Battery: A Reliable Energy Storage Solution for a Sustainable Future

Previous:CATL brings liquid cooled CTP energy storage solution to Japan International Smart Energy Week

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |