BMW has six main electric models, including BMW i3 pure electric, i8 plug-in hybrid sports car, five series 530Le plug-in hybrid medium-sized passenger car, X1 drive 25Le plug-in hybrid compact SUV, X5 drive 40e plug-in hybrid Medium and large SUV, 7 Series 740Le plug-in large hybrid vehicle. In the BMW series, only the i3 is pure electric. The following focuses on sorting out the relevant information of i3 battery packs, modules and batteries, and explaining the manufacturing process of i3pack. Finally, summarize the main characteristic parameters of BMW's full range of electric vehicles that have been personally compiled today in a table for reference.

This one is i8, mainly because it is more beautiful :)

1 Basic situation of BMW i3 pure electric battery pack

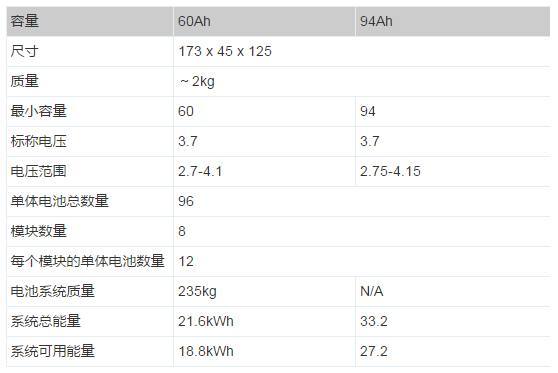

The battery pack, the power battery pack of I3, currently has two specifications, the power is from 22kWh and 33kWh, and the volume and structure of the two battery packs remain unchanged. The energy density of the two battery packs must be different. In Samsung SDI's energy battery series, there are two batteries of 60Ah and 94Ah. After replacing 60Ah with 94Ah, the total energy of the battery pack is increased to 33kWh. The 22kWh battery pack has a capacity of 60Ah and a full voltage of 353V; the total weight of the battery pack is about 235kg, and the specific energy is 93.6Wh/kg. The 33-degree electric battery pack has a capacity of 94Ah, the voltage remains unchanged at 353V, and the unique power is about 140.4Wh/kg.

The parameter comparison between 60Ah and 94Ah batteries is as follows:

The i3 has a cruising range of 130 kilometres with 22kWh, upgraded to 33kWh, with a cruising range of 183km. The power consumption per 100 kilometres is about 15.2kWh.

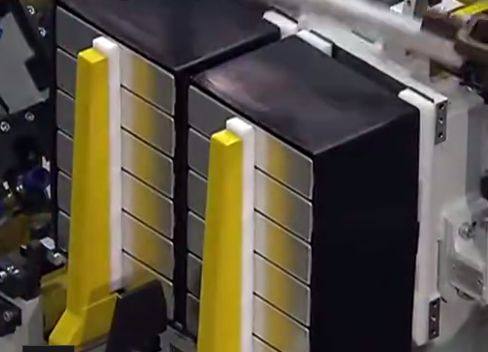

Module, I3 battery pack consists of 8 modules; each module has 12 cells in series, a total of 96 cells in series, as shown in the figure below.

As far as the current BMW I3 is concerned, its power battery has always been a square aluminium shell battery, which Samsung SDI provides. Its rated voltage is 3.7V, and the voltage limit range is 2.8-4.1VDC. The battery's specific energy is Above 120Wh/kg. The internal resistance is about 0.5 mΩ. There is no clear information about the technical route of the battery. Still, it is estimated from the energy density of the pack and the cell voltage that it should be ternary lithium or lithium cobalt oxide battery.

94Ah battery cell parameters: rated voltage: 3.7V, voltage range 2.75V-4.15V; recommended charge/discharge current 0.33 C (31A); cycle life: 80% deep discharge cycle for 3200 cycles, the remaining capacity is as high as 80% (Under 94A discharge current); the maximum discharge current is continuous 1C and peak value 4.3C (413A<5s); the maximum charging current is continuous 0.5C; size: 173*125*45mm; battery weight: 2kg ;Charging temperature range: 0℃ ~ 60℃; discharging temperature range: -25℃ ~ 60℃.

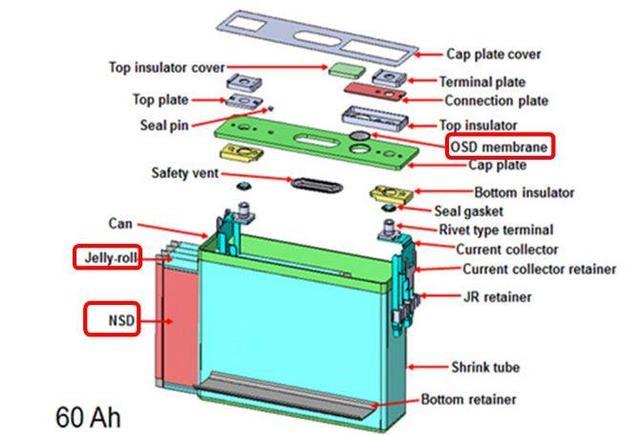

The battery structure diagram is as follows:

The unique safety structure on the battery cell is as follows:

Acupuncture safety protection device (NSD, Nail Safety Device). This metal layer, such as copper foil, is added to the core's outermost surface. When acupuncture occurs, the primary local current generated at the acupuncture location quickly reduces the current per unit area through the large size of the copper sheet, preventing local overheating of the acupuncture location and slowing down the occurrence of battery thermal runaway.

Overcharge Safety Device (OSD, Overcharge Safety Device), currently this safety design can be seen on many batteries. Generally, it is a metal sheet used in conjunction with the fuse, and the fuse can be designed on the positive current collector. The pressure generated inside the battery during overcharge causes the OSD to trigger an internal short circuit, which produces an instantaneous high current so that the fuse is blown, thereby cutting off the inner current loop of the battery.

2 Manufacturing process

The manufacturing process of the i3 battery pack is shown in a video, where the low-voltage wiring harness is not shown. The typical steps are listed below in order.

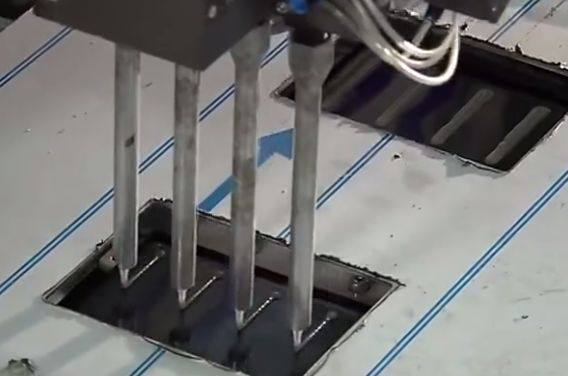

1) Dust removal of the cell, electrostatic adsorption of the dust on the surface of the square cell to prevent the dust from affecting the performance of the glue.

2) Glue, apply glue on the side of square battery cells so that the cells inside the battery pack are bonded to each other as a whole. What type of glue is applied, and no exact information has been found for the time being.

3) Configure structural parts for modules, manually select plastic pallets and aluminium alloy side plates from the material box to do small battery modules.

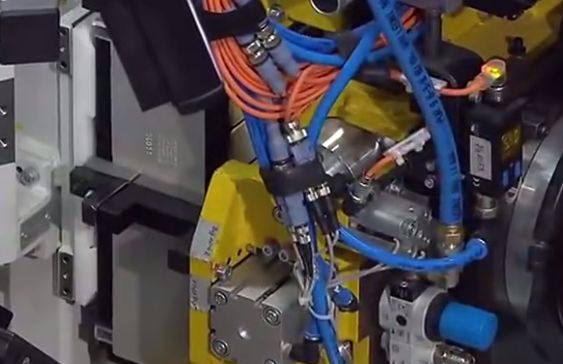

4) In The small module assembly process, the robot assembles the small module. The two stations on the turntable are the front and back processes. The battery cell bracket and the small module housing are added, respectively. Each small module contains 6 square cells.

5) Module assembly. Place two small modules side by side and fix them with aluminium alloy plates on the outside. After subsequent welding procedures, a complete module is formed.

Install aluminium alloy side panels.

6) Add module wiring harness, add temperature sensor and voltage acquisition wiring harness to the battery pack.

7) The module is equipped with a module cover and transported to the pack assembly process.

8) Hoisting box, empty aluminium alloy pack box.

9) Water cooling pipeline installation

10) Install MSD

11) Connect the high-voltage box

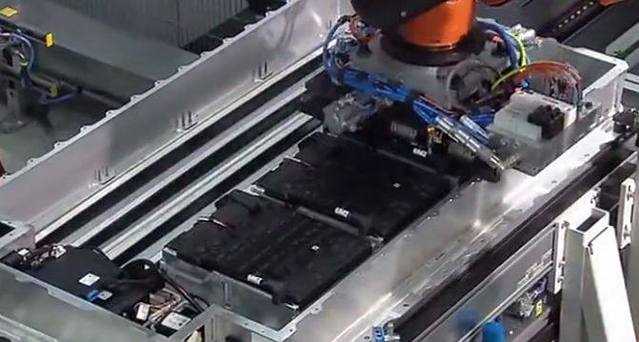

12) Place the modules, place the modules one by one in the fixed position of the packing box.

13) Module fixing bolt

14) The module is placed and fixed, and it flows into the next process

15) For a high-voltage connection, manually insert the high-voltage connector on the module, and connect all eight modules in series. I3 uses quick-plug connectors, which are safe and cost-effective.

16) Install the box cover. The box cover is a flat plate, which seems to have a little strength design. As Tesla does not have a body, this design should be related to the installation position and form on the chassis.

17) Fix the box cover, and screw the two robots at the same time. The green one is a plastic press block. The screw density is very high, the box cover and the box body are connected as a whole, so the box cover does not need strength.

18) Test, after all, assembly is completed, flow to the test bench.

Next:Second-generation lithium battery for industrial vehicles

Previous:In November, China power battery installed capacity ranking list was released!

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |